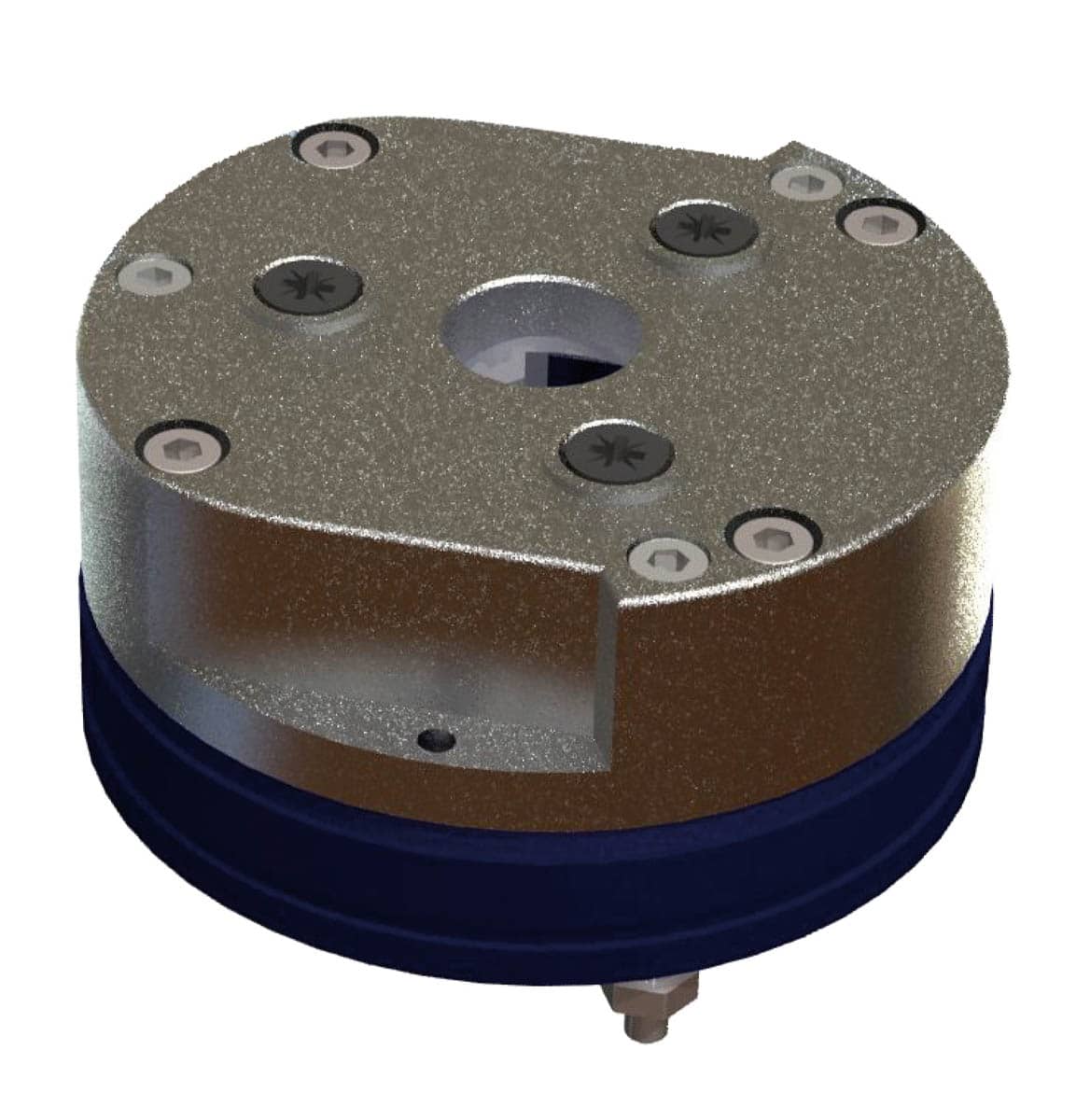

brakes for electric motors

We supply from our programme electromagnetic AC and DC brakes for electric motors from Temporiti. Tempoiti s.r.l. produces electromagnetic AC and DC brakes for electic motors since 1965. This company has two production plants with an area of 1500 square meters each. One specializes in the construction and mounting of the brakes and the other in the production of electrical components.

The production of the brakes depends on the customers specific application as well as on different technical requirements. Temporiti s.r.l. is certified with the quality system ISO-9001 since 2001. Considering these quality standards new brakes will be developed and existing models will be improved.

As the German general agency for Temporiti we offer the complete range of reliable and competitive AC and DC brakes. Many of these articles are available to purchase directly from our stocks in Kalefeld.

We are looking forward to your enquiry.

The Tempoiti Brakes correspond to the following norms:

- 98/37/EWG machinery directive

- 73/23/EWG low voltage

- 93/68/EWG electromagnetic compatibility

- 60335-1-CEI security of electric domestic appliances

- Norm 0580/VDE

- Certificate UL/CSA

- Certificate ISO 9001:2010

- 95/16/CE: TÜV

- Atex flameproof motor group II class1 GD d T6 IIC Zertifikat TUV IT 10 ATEX 044 Q

- New machine guideline

Applications are mainly found in power transmission. Especially in electric motors, gearmotors, DC motors, brushless motors and in industry vehicles (forklifs, construction and industrial cranes and other lifting systems) with a wide range of braking torques from 0,1 Nm to 4000 Nm.

The choice of brake is dependant on the corresponding braking torque (Mf) and determines the choice of brake used as per per the following criteria:

1) the total moment of inertia Itot [kg*m²] of the rotating parts relative to the drive shaft

2) the maximum speed [min-1] of the motor;

3) the maximum braking time tf [sec];

4) the brake torque ML [Nm], acting on the system for example by a load to be lifted or by a moment of resistance

5) the working frequency of the brake that means the number of operations of the brake per hour m [h-1]. Besides the above mentioned data additional information like mean ambient temperature and paticularly environment conditions (e.g. humidity, dust etc.) is extremely useful. Mounting position is also important in order to determine the most efficient functionality of the brake.

Further information at the following: http://www.temporiti.it/DE/Calculation-de.htm