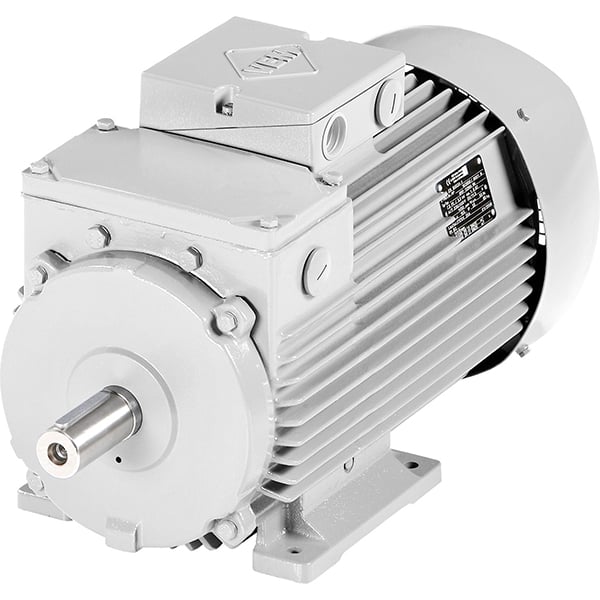

Electric Motors & Generators

VEM

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Low-voltage motors Frame 56 to 450

KMMP GmbH is an official appointed agent for VEM products both in the USA and Southern Africa.

We have in both regions our own branches and Sales offices to provide fast and effective service.

The VEM group has become known as an innovative multifaceted Electric motor producer in the following sectors: Mechanical Engineering, Plant Construction,Chemical & Oil & Gas industries, Wind Power, Transport Engineering, Steel & Rolling Mills to name a few.

Factories located in Wernigerode, Zwickau and Sachsenwerk collectively manufacture motors from 0,06 kW – 42 MW in various standard, slipring, inverter compatible and customised formats.

The latest efficiency standards form a large part of VEM’s ongoing global environment and energy saving responsibility- Efficiency class up to IE4.

Below you find an example of available motors from VEM

IEC standard motors with squirrel-cage rotor

Frame sizes 56 – 315, Output 0,06 kW to 160 kW

Efficiency class upto IE3

Speed 3000, 1500, 1000, 750, 600, 500 1/min

and pole-changing combinations

IEC standard motors with squirrel-cage rotor

Frame size 280, Output 75 kW to 90 kW

Efficiency class IE4

Speed 3000, 1500 1/min

Slipring motors

Frame sizes 132 – 315, Output 2,2 kW to 250 kW

Duty S1, S3 und S4/5

Speed 1500, 1000, 750, 600 1/min

Three-phase compact drives

Output 0,55 kW to 22 kW

Efficiency class upto IE5

Variable speed three-phase drives with squirrel-cage rotor

Output 0,75 kW to 1000 kW

Three-phase motors for use in mechanical

Smoke and heat extraction devices to DIN EN 12101-3:2015

for temperatures of 200, 300 and 400 Grad C

Output 1,5kW to 710 kW

Efficiency class upto IE3

Drive solutions for the steel and rolling mill industry

Three-phase roller table motors, 0,3 kW to 290 kW

Three-phase roller table gear motors, 0,4 kW to 450 kW

Three-phase motors for cranes in steel mills, 2,3 kW to 430 kW

Modifications:

Foot – and flange design

Assembled brake

Assembled star-delta switch

With thermal winding protection

Pole switching

Voltage switching

Memory version ( RFID transponder )

With encoder ( IGR ) or tachogenerator

With assembled forced cooling

Possible cooling types:

Self ventilated, IC 411

Forced ventilated, IC 416

Forced ventilated, IC 418

Non-ventilated, IC 410

Water-cooled, IC 71W ( IC31W )

for mains-powered motors efficiency classes according to IEC/EN 60034-30-1/IEC/EN 60034-2-1

for motors with variable speed efficiency classes according to IEC/EN 60034-30-2/IEC/EN 60034-2-3

AEM

With 70 years of experience in the field of electrical engineering, is AEM ( Anhaltisches Elektromotorenwerk Dessau ) your partner for special, high-quality electric machines as drive solutions or power generation.

Whether you require a single piece or a small batch – AEM will flexibly and reliably develop and manufacture three-phase motors and three-phase generators to meet your needs. The primary goal is to manufacture products of the highest quality in accordance with quality management DIN ISO 9001.

Since 1991 Kurt Maier Motor-Press GmbH sells and distributes products of AEM mainly in southern Africa and USA within our own network organisations

Below we summarize some products made by AEM

Asynchronous-Three phase motors

Our range of products includes three-phase asynchronous motors and three-phase synchronous motors.

Simple, “independent” start-up, start-up against high counter torques, long service life, high speed capability, high level of efficiency

Our high-quality asynchronous motors are available in squirrel-cage motor or slip ring motor versions. They are characterised by an extremely robust construction and high reliability. The power range of our electric motors is between 160 and 5,000 kW, however other power ratings are also available.

Shaft height: up to 800

Protection degree: up to IP 68

Cooling system: up to IC 86W7

Speed: up to 3,600 rpm

Insulation class: F and H

in combination with gears, brakes, heating systems, etc.

Additional components:

In order to adapt the machines to different applications and for monitoring and documentation purposes, the machines can be equipped with the following additional devices:

brakes

incremental encoder for speed measurement

PTC, KTY and PT 100 for thermal monitoring and the protection of motor windings and bearings

carbon brush monitoring

anti-condensation heating for fluctuating ambient temperatures

voltage regulator

starting resistors

leakage sensors

couplings

slip ring area lighting

Crane Drives

Robust and reliable – AEM crane motors

The transition from DC technology to the modern age of power electronics created new challenges for three-phase machinery, and in particular for speed-controlled three-phase motors with cage rotors. We developed robust motors as crane drives for numerous applications, including for the port, shipping/offshore and steel industries. These applications require special construction, as well as the electrical design of the machinery.

The tried-and-tested technology of using slip-ring motors as crane drives is increasingly in demand. The machines carry out heavy starts without any negative effect on the rotor winding and are highly suited to operating modes such as S3. AEM crane motors are inspected and approved by shipping classification societies and can therefore be used in both marine and offshore installations.

Mill Drives

For electric motors, mills count amongst the most complex machines in the industry. The heavy starting alone makes the start-up of an electrical machine noticeable. In addition to this, there are also frequent ignitions and unwanted vibrations. A ball mill, which already has a high moment of inertia in itself, is filled with limestone in cement plants – or coal in thermal power plants – upon start-up, making it more difficult to start the engine. Our tube-cooled U series is specially designed for heavy starting. The machines with squirrel cage rotors are very well suited for operation on the converter and are calculated for frequent ignitions by our engineers using special winding systems. The slip ring rotor version allows for an additional increase in starting torque. Machines from the A series in versions with air-to-air or air-to-water heat exchangers are well suited for vertical coal mills in coal-fired power plants. The special design of the engine can easily absorb the vibration of the mill while still remaining fully functional. The operating point and start-up ability determine the characteristics of the mill. Our drives are used in cement, coal and paper mills, amongst others.

Test Stand Machines

High-Speed Asynchronous Machines

We offer special drive solutions for motors, aggregates, rollers and turbine test stands, amongst others. Our high-speed machines in open constructions or with water jacket cooling systems are specifically calculated and implemented according to the speed-torque characteristics for different operating points. Thanks to the use of modern converter technology, the high-maintenance gear box is no longer required in the test field.

Excavator Drives

Bucket wheel excavators and belt stackers require optimum control in order to work effectively. AEM motors successfully meet these requirements as variable speed drives. Our engineers ensure the special design of the often overloaded machines, so as to ensure trouble-free operation in conditions such as high ambient pollution and violent system vibration.