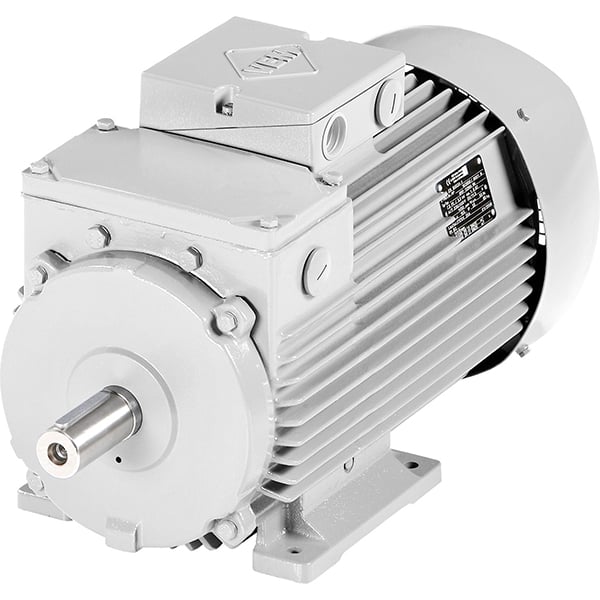

Electric Motor

VEM

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Low-voltage motors Frame 56 to 450

KMMP GmbH is an official appointed agent for VEM products both in the USA and Southern Africa.

We have in both regions our own branches and Sales offices to provide fast and effective service.

The VEM group has become known as an innovative multifaceted Electric motor producer in the following sectors: Mechanical Engineering, Plant Construction,Chemical & Oil & Gas industries, Wind Power, Transport Engineering, Steel & Rolling Mills to name a few.

Factories located in Wernigerode, Zwickau and Sachsenwerk collectively manufacture motors from 0,06 kW – 42 MW in various standard, slipring, inverter compatible and customised formats.

The latest efficiency standards form a large part of VEM’s ongoing global environment and energy saving responsibility- Efficiency class up to IE4.

Below you find an example of available motors from VEM

IEC standard motors with squirrel-cage rotor

Frame sizes 56 – 315, Output 0,06 kW to 160 kW

Efficiency class upto IE3

Speed 3000, 1500, 1000, 750, 600, 500 1/min

and pole-changing combinations

IEC standard motors with squirrel-cage rotor

Frame size 280, Output 75 kW to 90 kW

Efficiency class IE4

Speed 3000, 1500 1/min

Slipring motors

Frame sizes 132 – 315, Output 2,2 kW to 250 kW

Duty S1, S3 und S4/5

Speed 1500, 1000, 750, 600 1/min

Three-phase compact drives

Output 0,55 kW to 22 kW

Efficiency class upto IE5

Variable speed three-phase drives with squirrel-cage rotor

Output 0,75 kW to 1000 kW

Three-phase motors for use in mechanical

Smoke and heat extraction devices to DIN EN 12101-3:2015

for temperatures of 200, 300 and 400 Grad C

Output 1,5kW to 710 kW

Efficiency class upto IE3

Drive solutions for the steel and rolling mill industry

Three-phase roller table motors, 0,3 kW to 290 kW

Three-phase roller table gear motors, 0,4 kW to 450 kW

Three-phase motors for cranes in steel mills, 2,3 kW to 430 kW

Modifications:

Foot – and flange design

Assembled brake

Assembled star-delta switch

With thermal winding protection

Pole switching

Voltage switching

Memory version ( RFID transponder )

With encoder ( IGR ) or tachogenerator

With assembled forced cooling

Possible cooling types:

Self ventilated, IC 411

Forced ventilated, IC 416

Forced ventilated, IC 418

Non-ventilated, IC 410

Water-cooled, IC 71W ( IC31W )

for mains-powered motors efficiency classes according to IEC/EN 60034-30-1/IEC/EN 60034-2-1

for motors with variable speed efficiency classes according to IEC/EN 60034-30-2/IEC/EN 60034-2-3